ATi Water & Wastewater

Quality Monitoring

Badger Meter's smart water solutions now encompass flow measurement, temperature, pressure and water quality parameters. With products from Analytical Technology, Inc. (ATi), a Badger Meter brand, we have a comprehensive water quality monitoring offering that is transforming the water industry and enhancing how users manage their water systems.

Now, data from advanced metering infrastructure (AMI) systems can also be used for water quality surveillance and response systems (SRS). This helps operation managers monitor their system for abnormalities and respond to problems immediately to minimize potentially dangerous outcomes. Combining water quality monitoring with AMI and SRS provides full visibility and valuable insights that drive better results, optimize operations and reduce costs.

ATi products are employed in a wide array of applications, ranging from municipal pre-treatment programs to wastewater treatment discharge monitoring to industrial effluent compliance.

ATi offers a diverse range of pioneering, industry-leading water quality monitoring solutions, from the latest in digital, Smart Water quality monitoring technology to potable, process and wastewater monitors and transmitters.

As advocates of collaborative, customer-focused innovation, ATi also delivers bespoke engineered solutions to suit individual site requirements, including dual and triple validation water quality monitoring and tailored, modular smart water quality systems, with customer specified digital sensors.

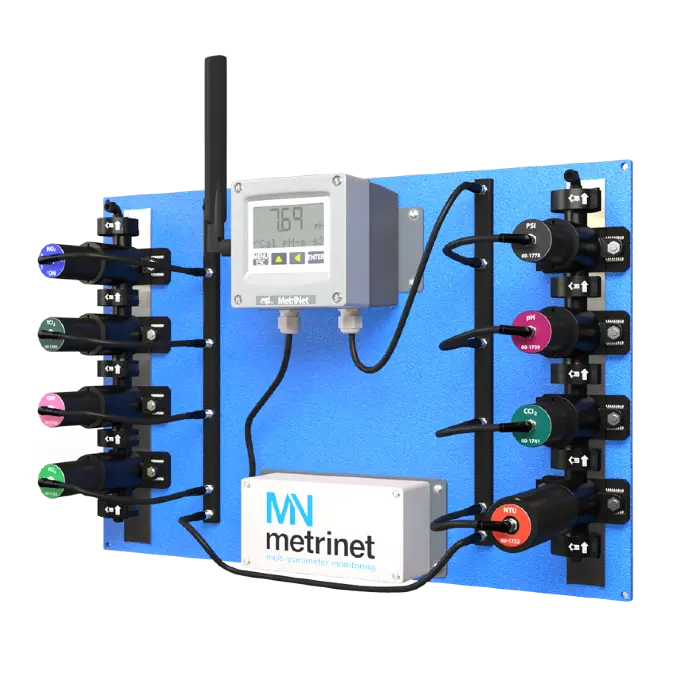

MetriNet

ATi’s MetriNet solutions are a pioneering, field-proven breakthrough in water quality monitoring. With 16 parameters to choose from, the modular nature allows unique monitoring solutions for individual site requirements across utilities, food & drink, industrial, healthcare, leisure and HVAC.

Analysing water quality data from our range of MetriNet smart M-Node sensors, we are able to extract deeper, real-time insights, allowing water utilities to enhance operational efficiencies.

Implementing MetriNet helps to enhance analytical platform performance, identify leaks, improves strategies and enables informed decisions, removing the guesswork from planning and investment.

MetriNet Features:

M-Nodes

- Electronic assemblies are galvanically isolated from the power supply and communication link

- Zero and span data stored internally so calibration can be done anywhere

- Internal clock records total run time on the sensor

- Calibration timer can alert users when calibration is due

- Two alarm set points are available

- Sensor diagnostics report problems in clear message form

Controller

- Accepts up to 8 M-Node sensor inputs

- Stores data at user defined intervals from 0.1-60 minutes

- Stores over 300K values, or 30 days of data for 8 sensors at 1 minute data interval

- Options for cellular modem, Wi-Fi, or wired Modbus RTU, Modbus TCP/IP, Ethernet/IP or Profibus DP

- Internal Micro-SD RAM card provides data backup in the event of communication problems

- Addition of a low power solenoid valve allows intermittent sample flow

- Sensor diagnostics report problems in clear message form

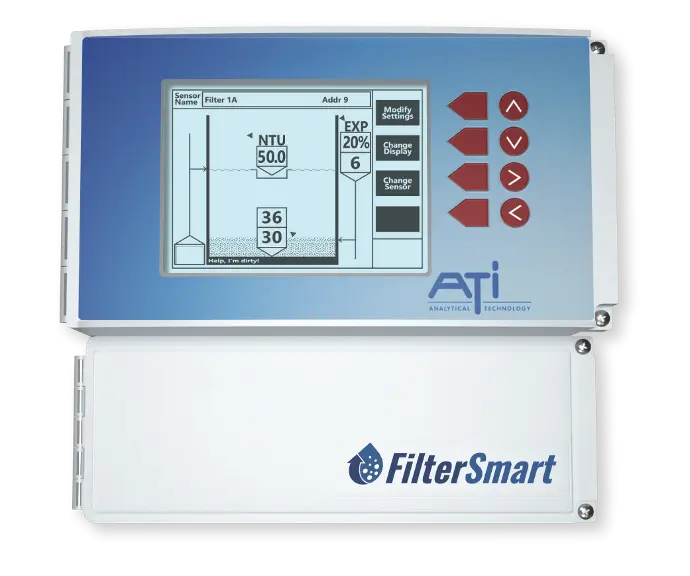

FilterSmart

ATi’s FilterSmart Backwash Monitor is revolutionising the way water professionals manage their gravity filters.

Until now, operators have relied on two surrogate measurements to manage the backwash process: flow rate and time. FilterSmart directly measures the parameters of specific interest – media expansion and turbidity. These two trends together present a clear picture of what’s going on during the backwash, allowing operators to ‘see’ into the process like never before. FilterSmart simplifies filter optimisation because its 24/7 monitoring takes the place of countless manual hours of data collection.

The FilterSmart sensor is located in the top of a gravity filter just below the top of the wash trough. During a backwash, the ultrasonic sensor tracks the level of the media and the turbidity sensor measures how clean or dirty the wash water is as it flows into the wash trough. These two measurements produce trends that together provide an extremely accurate profile of the backwash and become a powerful tool for optimising filter performance. Equipped with this insight, operators can virtually eliminate media loss and mud-ball formation, in most cases reduce water usage, and improve overall filter health and efficiency.

EchoSmart

EchoSmart is an underwater interface level analyzer technology that is built on a digital platform. This allows the analyzer to be located in the sensor. The result is greater flexibility in equipment configuration options, enhanced communication capabilities and reduced installation costs. EchoSmart Interface Level Analyzers are unique in that our Smart-Sensor technology enables the control and monitoring of up to 16 Smart Sensors from one EchoSmart Controller. This allows for field networks of sensors, thereby lowering the ‘per-tank’ cost. These field networks can also be created wirelessly, eliminating costly conduit and cabling runs.

EchoSmart sensors employ interface-detection algorithms developed exclusively by ATi with proven performance across the UK, USA and around the world.

EchoSmart is adaptable and can be programmed to suit various tank sizes and designs. Three sensor models provide a solution for most applications: the standard sensor with multi-flex assembly for when surface skimmers are present, the self-cleaning sensor for applications without surface skimmers, and the sensor with turbidity that offers further insight into water clarity.